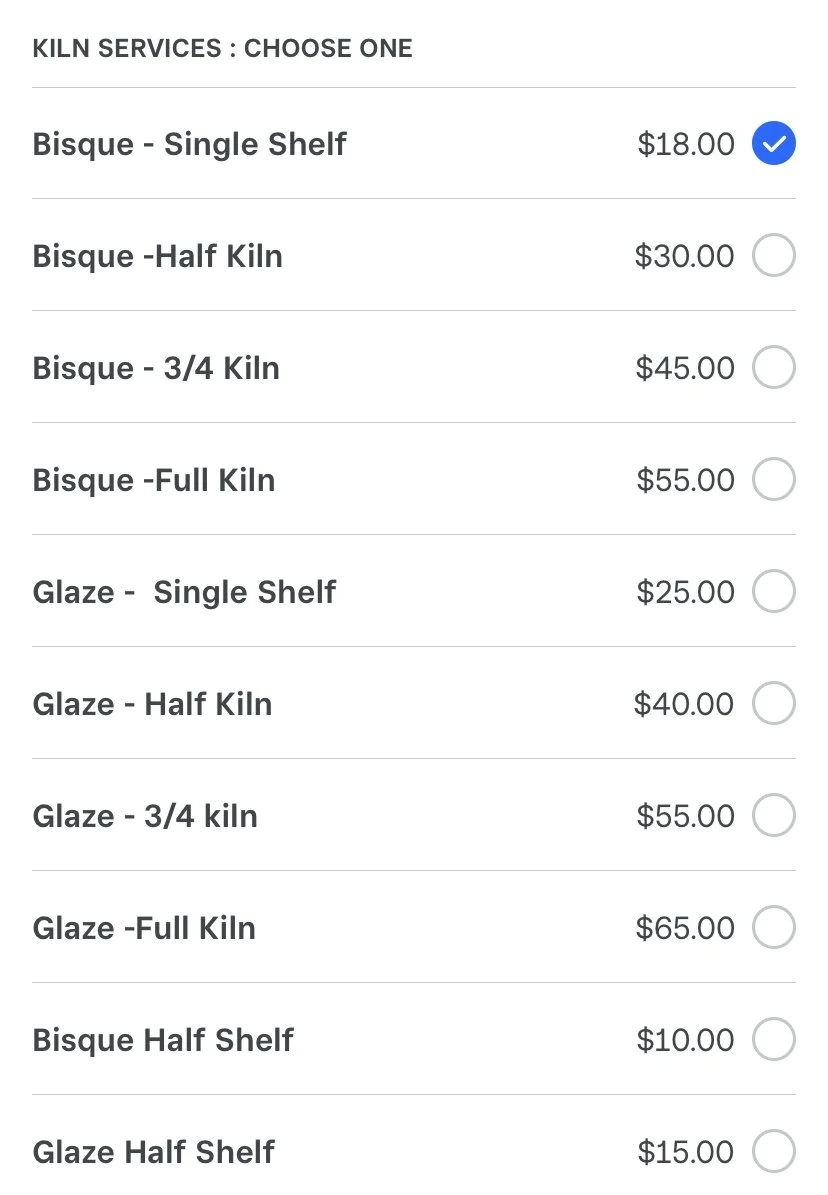

Kiln Services - Mid Range Kiln Firings for Non Workshop Students

Kiln Services - Mid Range Kiln Firings for Non Workshop Students

Drop off wares Thursday - Monday from 11-5pm to be fired.

Located at 20 Lakeview drive unit #208 in Nederland Colorado.

I will ONLY fire clay I 100% know that brand and firing range on. Please have the manufactures name, the clays name, and the firing temperature it matures at ready for me. This sounds really strict but a kiln is a huge investment and the wrong clay could easily ruin it. Thank you for understanding and keeping me and my equipment safe!

Dimensions allowed:

We have a minimum of 1.5” Wide x 1.5” Long x 3/4” Tall = about the size of a silver dollar. Tiny objects can get lost and misplaced easily.

We have a maximum of 8” Wide x 8” Long x 14” Tall

The amount of pieces you can fit inside a bisque kiln load will be much more than a glaze kiln load. When you load a bisque kiln the pots can be stacked inside each other but you CAN NOT do this during a glaze firing. In a bisque firing we use only two shelves inside the kiln. The bottom shelf and another one half way up the kiln. We do this because we can stack smaller object inside larger ones with no fear of them fusing together. The shelf half way up will aid in weight distribution as well as a barrier during the risky bisque firing. A bisque firing is a lot riskier than a glaze firing because the clay goes through a chemical change called quartz inversion. See our chart in the pictures to better understand this process. When we glaze fire pots cant be touching because the glaze (liquid glass) will fuze the pots together. This means that ever single item in the glaze kiln must have its own kiln shelf space, away form other pots.

Here is a rough estimate of pots per half kiln and full kiln of both firings, keep in mind, one half bisque load may equal one full glaze load.

Half Bisque Kiln: 20-65 pieces

Full Bisque Kiln: 40-100 pieces

Half Glaze Kiln: 7-15 pieces

Full Glaze Kiln: 10-35 pieces

This range changes depending on the size of your items. If you have all larger items like big bowls or vases you will have a lot less kiln room compared to if you made all orange sized bowls or mugs. You can fit more mugs in a kiln that are 1lb than you can 1lb bowls because of the straight up and down walls of the mugs.

Turn over times can range dramatically depending on the time of the month and the stage of firing cycles we are in. Our kilns need to be full to fire. It’s very common for us to fire bisques mid month and glaze kilns to be fired towards the beginning and the end of each month. If you miss our firings, it could be up to 4 weeks before we are firing that temp again. If we don’t have enough pottery to fill a kiln, those pots could be pushed back until we do. On average, we fire around 6 bisque loads and around 15 glaze loads per month.

Spinning Silica is not responsible for ruined or cracked pots. You as the maker understand that there is no guarantee in ceramics. Do not count on a piece of work to come out 100% until it is completed. There are so many stages in ceramics, and they can all go wrong. It is part of the learning curve and you can always make it again, I promise it will be better the second time anyway! I will always do my best to help you understand what went wrong in the process so you can improve in that area for your next go. Don’t be afraid to throw away/reclaim the ugly and try try again. Have FUN and lets make some art!